NON METALLIC GASKETS MANUFACTURER

Non-Metallic Gaskets are made of Graphite with or without insertion, Asbestos-free, Rubber or Teflon materials. Soft gaskets are used in a wide range of applications. It can be produced in a variety of cut shapes or can be provided in sheet or rolls.

The different types of gaskets are

Non-Asbestos Materials

PTFE Based Materials

High Performance Graphite Materials

Elastomeric Rubber Materials

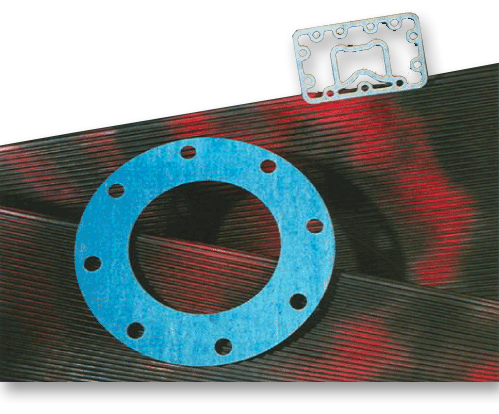

Bluegard Gasketing

Compressed Inorganic Fiber Gasket

Gylon Gasketing

Bluegard Gasketing

BLUE GARD gasketing provides superior sealability and excellent creep relaxation. BLUE GARD gasketing is produced from special blends of synthetic fibers, fillers and elastomeric binders. BLUE GARD gasketing serves as a general purpose gasket material across a wide range of industrial applications. STYLE 3000 Water, aromatic hydrocarbons, oils, gasoline, mild acids and alkalies. STYLE 3400, 3200 Water, saturated steam, inert gas, mild acids and alkalies. STYLE 3700 Water, saturated steam, mild acids, strong caustics of moderate concentrations.

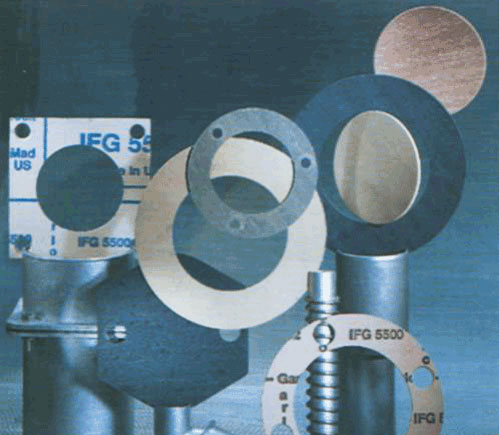

Compressed Inorganic Fiber Gasket

A specially formulated, all purpose family of Garlock inorganic asbestos-free fiber gasketing which exceeds the parameters of aramid fiber reinforced gasketing in thermal stability, torque retention, sealability and weight loss. As inorganic fibers do not oxidize IFG 5500 provides greater thermal and dimensional stability during process cycling. IFG is produced to meet most service requirements. The IFG material also offers flexibility when writing corporate piping specifications – giving you the right gasket for the right application – the first time.

IFG 5500 Water, saturated steam, aliphatic, hydrocarbons, oils, gasoline and mild acids

Gylon Gasketing

Garlock GYLON gasketing is truly a superior and unique material. The exclusive properties of GYLON gasketing are combined to deliver its superior performance to comply with today’s clean air requirements through sealability and torque retention. Asbestos-free GYLON gasketing routinely outperforms all conventional PTFE products by drastically minimizing gasket creep and cold flow problems. Typical conditions for GYLON gasketing are found in the food, chemical and petrochemical industry, pulp and paper plants and pharmaceutical industry. For special chemicals consult the chemical resistance chart or contact Garlock.

GYLON Style 3500 and 3501 E Standard

These general purpose gasketing materials offer significant advantages over conventional PTFE in regard to function ability at higher temperature/pressure combinations. Style 3500 and 3501 E GYLON gasketing conform to FDA specifications. Often used in chemical processing and hydrocarbon processing industries.

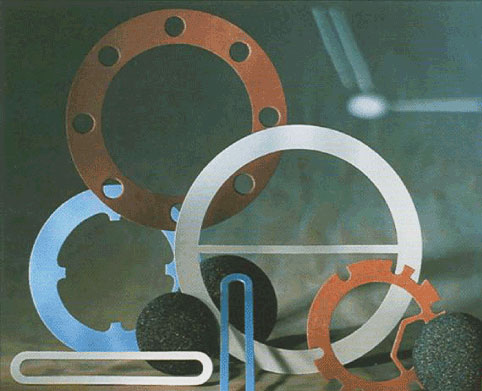

ELASTOMERIC GASKET MATERIALS

Elastomeric gaskets with different chemical and mechanical properties are being supplied to oil and petrochemical industries, sewerage & chilled water sector and exclusively for Potable water applications. There are varieties of elastomeric gaskets, gasket sheets/rolls with different sizes which are produced against international standards such as ASME B16.21, BS EN 1514-1, JIS etc.

The materials available with us are as follows:

- Neoprene

- Neoprene W/ Cotton Reinforcement

- EPDM (Ethylene Propylene Diene Monomer)

- EPDM W/ Cotton Reinforcement

- EPDM (WRAS Approved) for Potable Water Applications W/ 2 Ply Cloth Reinforcement.

- NBR (Nitrile Butadiene Rubber)

- Viton (FPM)

- Silicon

- SBR (Styrene Butadiene Rubber)

- Kalrez (FFKM

SPTFE ENVELOPED GASKETS

Polytetrafluorethylene ( PTFE) Envelope Gaskets are used for sealing all acid and caustic media PH 0-14, with the gasket material being used as a filter gasket. envelope gaskets, resistant to virtually all chemicals and exhibiting excellent non-stick properties. No risk of process contamination, provided by strict process control and manufactured by Q-GER.

Envelope Gasket using Compressed Non-Asbestos Fiber Sheet and Flexible Graphite in the core. Common uses for PTFE Envelope Gaskets and materials below.

- Food & Chemical Industries

- Piping service

- Pharmaceutical Industry

- General purpose for glass line industry.

The PTFE envelopes are available in standard and non-standard dimensions with us.

PTFE envelope gaskets are available in the following configurations.