METAL RING JOINT GASKET MANUFACTURER

METAL RING JOINT GASKET MANUFACTURER

Ring Joint Gaskets are metallic sealing rings suitable for high pressure and high temperature applications and are fitted in ring grooves. They are widely used in the Oil / Petrochemical industry and in valves and pipe work. Choice of material may be determined to suit higher temperatures and aggressive media. They comply with ASME B16.20 standards and API spec 6A.

PRINCIPAL TYPES OF MATERIALS

(Other alloy materials available upon request.)

| Metal | Maximum Hardness |

| Soft Iron |

90 BHN |

| Low Carbon Steel | 120 BHN |

| F5 Alloy Steel | 130 BHN |

| Type 410 S/S | 170 BHN |

| Type 304 S/S | 160 BHN |

| Type 304L S/S | 160 BHN |

| Type 316 S/S | 160 BHN |

| Type 316L S/S | 160 BHN |

| Type 347 S/S | 160 BHN |

| Type 321 S/S | 160 BHN |

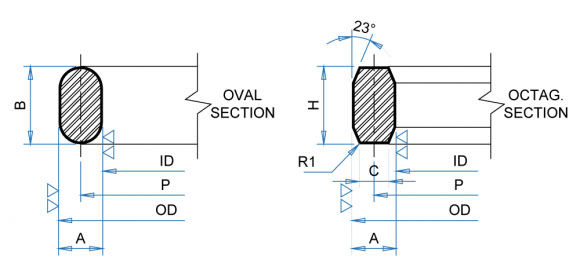

QRTJ TYPE R RING JOINT GASKET

The QRTJ type R metal ring joint gaskets are manufactured according to ASME B16.20 and API 6A. The type R oval configuration was the original design and was followed by the type R octagonal which offered more specific contact areas.

NOTE

All dimensions are in mm.

R30 is suitable for lapped flanges only.

Class 720, 960 and 10000 flanges to API 6B are obsolete. Data is for information only.

The 23° surfaces shall have surface finish no rougher than 1.6 µm (63 µin RMS).

B,H Variation in height throughout the entire circumference shall not exceed 0.5mm.

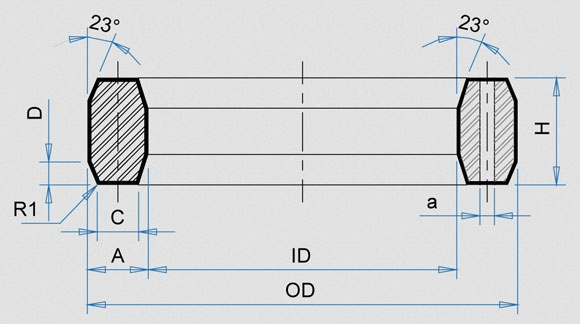

QRTJ TYPE RX RING JOINT GASKET

The QRTJ type RX metal ring joint gaskets are manufactured according to ASME B16.20 and API 6A. The type RX series is of higher strength materials designed primarily for well-head pressures of 700 bar and beyond.

NOTE

- All 23° surfaces on R and RX gaskets shall have a surface finish no rougher than 1.6µm Ra ( 63 µin RMS ).

- One pressure-passage hole illustrated in fig.1 < a >. Centerline of hole shall be located at midpoint of dimension “C“.

- Tolerance on these dimensions is +0, -0.38

- Tolerance on these dimensions is +0.50, -0

- Class 720,960, and 2900 flanges to API 6B are obsolete. Data is for information only.

- Crossover flange connection.

- A plus tolerance of 0.20 mm for width “A” and height “H ” is permitted, provided the variation in width or height of any ring does not exceed 0.10 mm throughout its entire circumference.

QRTJ TYPE BX RING JOINT GASKET

The QRTJ type BX metal ring joint gaskets are manufactured according to ASME B16.20 and API 6A. The type BX series is of higher strength materials designed primarily for special applications involving high pressures up to 20,000 psi.

NOTE:

- All 23° surfaces on BX gaskets shall have a surface finish no rougher than 0.8 µm Ra ( 32 µin RMS ).

- Radius “ R ” shall be 8 % to 12 % of the gasket height ”H ”. One pressure-passage hole required per gasket on centerline. See fig. 1

- A plus tolerance of 0.20 mm for width “A” and height “H ” is permitted, provided the variation in width or height of any ring does not exceed 0.10 mm throughout its entire circumference.